In Zell am Moos, all is still right with the world. This is the feeling that comes over a visitor when he drives over the green hills, past the blue lakes, to the small Austrian town that is home to FN Neuhofer. The mood is good, the entrepreneurial family exudes great cordiality. Sales for 2021 and 2022 are also satisfying. And work on the construction of new production, exhibition and office space could even be completed ahead of schedule. Despite all this, Neuhofer also has to contend with current challenges such as increased prices, long delivery times and the shortage of skilled workers.

The company is all the more pleased that the new building could be completed largely before the start of the supply crisis. As part of Vision 2025, the last specialists are currently implementing what they say is the largest investment in the company's history. "Surely there are still two years to go until 2025?" some may ask. "The project is not yet finished," explains Managing Director Franz Neuhofer. The Austrians' Vision 2025 also includes fully automated machinery. For example, the production line for MDF laths, the pallet packaging machine, the quality scanner or the wrapping line run largely automatically. "No employee loses his or her employment as a result of the automation of the systems," emphasizes Alexander Schachl, technical manager at Neuhofer. The employees affected are retrained and deployed elsewhere.

The Austrians are particularly proud of their digital printing machines: Here, skirting boards are "married" with flooring, explains Schachl. The flooring manufacturers with whom Neuhofer works provide samples of their products, to which the moldings are adapted. The resulting decors, in turn, are entered into a database. "In the past, moldings were primarily adapted to the floor, but today they are increasingly being adapted to the wall as well," explains the technical manager. With the digital printing system, it is also possible to create moldings with any design the customer wants.

The biggest innovation, however, is the third digital printing system, which went into operation in December 2022: With it, instead of a film applied to the substrate, entire boards made of MDF, metal, rigid plastic foam, flexible foam, three-layer spruce boards, pressboard, cardboard and glass up to a width of 250 cm can be printed. For example, profiled boards, planks, wall paneling and kitchen backsplashes can be customized.

It is also possible to print acoustic panels. FN Neuhofer has high hopes for this new product area. "This is a trend that will stay," Franz Neuhofer is convinced. Acoustic panels were also the focus of Neuhofer's exhibition space at the Domotex flooring trade show earlier this year. The company had unceremoniously recycled the equipment from the previous edition of the fair: it now adorns the entrance area of the showroom that has been created in the new building.

The wood experts are making the entrance area available free of charge to the community and various organizations from the region. For example, the fire fighters meet here. "We're opening up," emphasizes Helga Neuhofer, the managing director's wife, who works in marketing, referring also to the open days to which the manufacturer invited people after the completion of construction work in the summer of 2022. In addition to customers, numerous interested people from the surrounding area also came - with consistently positive feedback, as Franz Neuhofer emphasizes.

Above all, however, it was important to the team to present the new showroom to their customers. "Around 1,000 visitors were there," reports Helga Neuhofer. The showroom is divided into a DIY market area and a specialist trade area. For the DIY trade, the typical shelf assemblies and other POS material can be seen, which can be individually assembled on request.

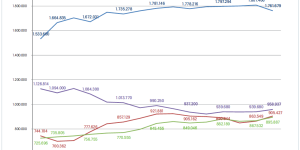

A total area of 14,550 m² was installed in one and a half years, with a planning period of just three quarters of a year. This increased production capacity by 50 percent, explains Neuhofer. The roof surfaces are covered by a 1-megawatt photovoltaic system. It covers one-eighth of the total electricity consumption. In addition, a new heating system was installed that runs on wood chips left over from production. In total, 54 million euros were invested.

Neuhofer already has further plans. In the future, the company's premises are to double in size, from 100,000 m² now to 200,000 m2. The manufacturer has already acquired one area for this purpose, and is working on others, according to Franz Neuhofer. The goal is to accommodate logistics, including a high-stack warehouse. "The important thing is that you already have the next vision and know where you are going," notes the managing director.

Menü

Menü

Newsletter

Newsletter